tunçer MaChıne

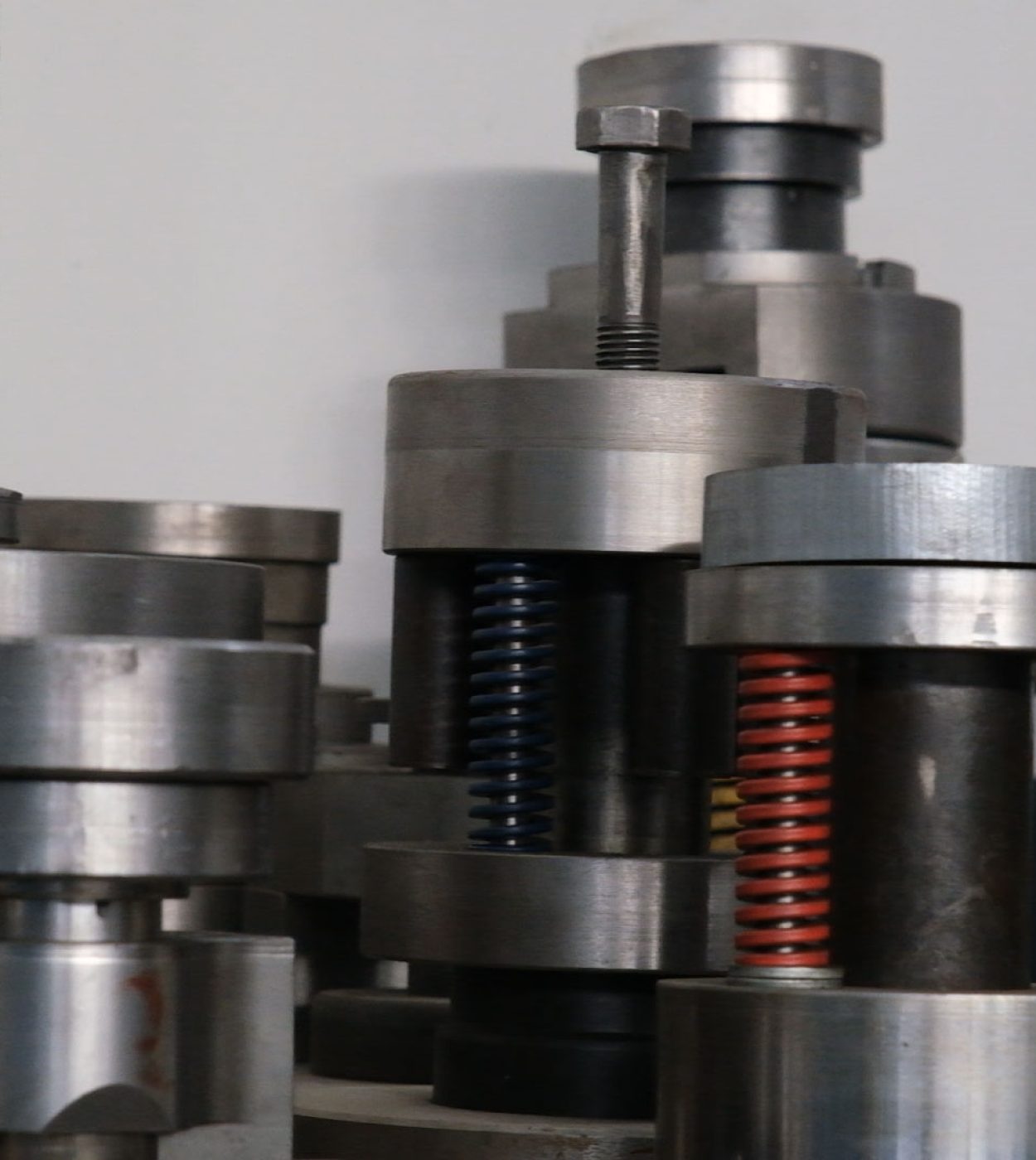

Our molds

What are sheet metal dies? In which areas are sheet metal dies used?

Tunçer Makina is one of the leading manufacturers of sheet metal dies used in industrial production processes. Using high-quality steel and alloy materials, it designs and manufactures custom sheet metal dies tailored to its customers’ needs.

Each die is machined on precision CNC machines according to the customer’s specifications and carefully inspected. During the design phase, the dimensions, shape, and processing requirements of the part to be produced are examined in detail, and a custom mold design is created accordingly.

Tunçer Makina’s team of experts continuously prioritizes quality and innovation to provide its customers with the most efficient and durable sheet metal molds. The dies produced have a wide range of applications in industries such as the automotive industry, white goods production, aviation, electrical, cage equipment, natural gas equipment, rubber support sheets, ceramics, decoration, PVC connection equipment, and many others.

To meet its customers’ needs, the company aims to provide not only high-quality products but also competitive prices and superior customer service. Additionally, by offering support for the regular maintenance and repair of molds when needed, it helps customers maintain uninterrupted and efficient production processes.

Tunçer Makina continues to support industrial production success by offering its expertise and experience in sheet metal molds to its customers.

Each mold is processed on precision CNC machines according to customer requirements and carefully inspected. During the design phase, the dimensions, shape, and processing requirements of the part to be produced are examined in detail, and a custom mold design is created accordingly.

Tunçer Makina’s expert team consistently prioritizes quality and innovation to provide customers with the most efficient and durable sheet metal molds. The molds produced have a wide range of applications in the automotive industry, white goods production, aviation, electrical, cage equipment, natural gas equipment, rubber support sheets, ceramics, decoration, PVC connection equipment, and many other sectors.

To meet its customers’ needs, the company aims to provide not only high-quality products but also competitive prices and superior customer service. Additionally, by offering support for the regular maintenance and repair of molds when needed, it helps customers maintain uninterrupted and efficient production processes.

Tunçer Makina continues to support industrial production success by offering its expertise and experience in sheet metal molds to its customers.

Coating Molds

It enables deep forming of sheet metal by pouring it into a mold. It is generally preferred for the production of hollow and deep parts.

Prototype Molds

It is used to produce sample parts before going into production. It plays an important role in the testing and development stages of the product.

Progressive Patterns

These are molds that perform multiple processes (cutting, drilling, bending, etc.) step by step within the same mold. They are ideal for mass production, saving time and money.

Cutting Molds

Ensures that the sheet metal is cut to the desired shape and dimensions. It is specially designed according to the product geometry.

Drilling Molds

Used to drill holes in sheet metal surfaces. Operates with high accuracy on parts where precision is critical.

Bending Molds

These dies are designed to bend or curve metal sheets into a specific shape. Specially designed die sets enable metal sheets to be bent into the desired shape by giving them the desired bending angles and curve radii.