About Us

Over 20 years of experience and evolving technology

Tunçer Makina Kalıp was founded in 2000 by Ömer TUNÇER and began its operations with mold production and assembly work.

ISO 9001:2015

ISO 45001:2018

ISO 14001:2015

For years, we have always strived to provide our valued customers with the best service and timely delivery, and we have acted in accordance with this principle, keeping pace with technological developments and the requirements of the age. Based on this, we have placed importance on total quality management, and in 2012, we completed our certification activities, taking our service philosophy one step further.

In 2020, in line with our growth, our machinery fleet and production facilities have reached larger capacities, and our product range has expanded. With our new facility established in the Manisa Organized Industrial Zone to meet your needs and requests, we provide services in the sectors listed below.

In line with our growth in 2020, our machine park and production facility have reached greater capacities and our product range has expanded. With our new facility established in the Manisa Organized Industrial Zone to meet your needs and requests, we provide services in the sectors listed below.

Areas of Practıce

Our Services

We are a company specializing in the production of sheet metal molds that require high precision. Thanks to our experience in die design and production, we offer customized solutions for cutting, bending, stamping, and progressive die needs. Our sheet metal molds, which are tailored to industry expectations, support efficient production in many areas, from automotive to white goods.

Each mold is custom-designed for each customer, ensuring the production of metal parts that are best suited to the project and offer the highest precision.

With our press forming services, we successfully carry out one of the fundamental steps in industrial production by giving metal sheets the desired shape under high pressure. With our modern press machines and experienced operators, we offer both speed and quality in mass production processes. Tunçer Makina is a reliable production partner for companies in various sectors in the production of custom parts.

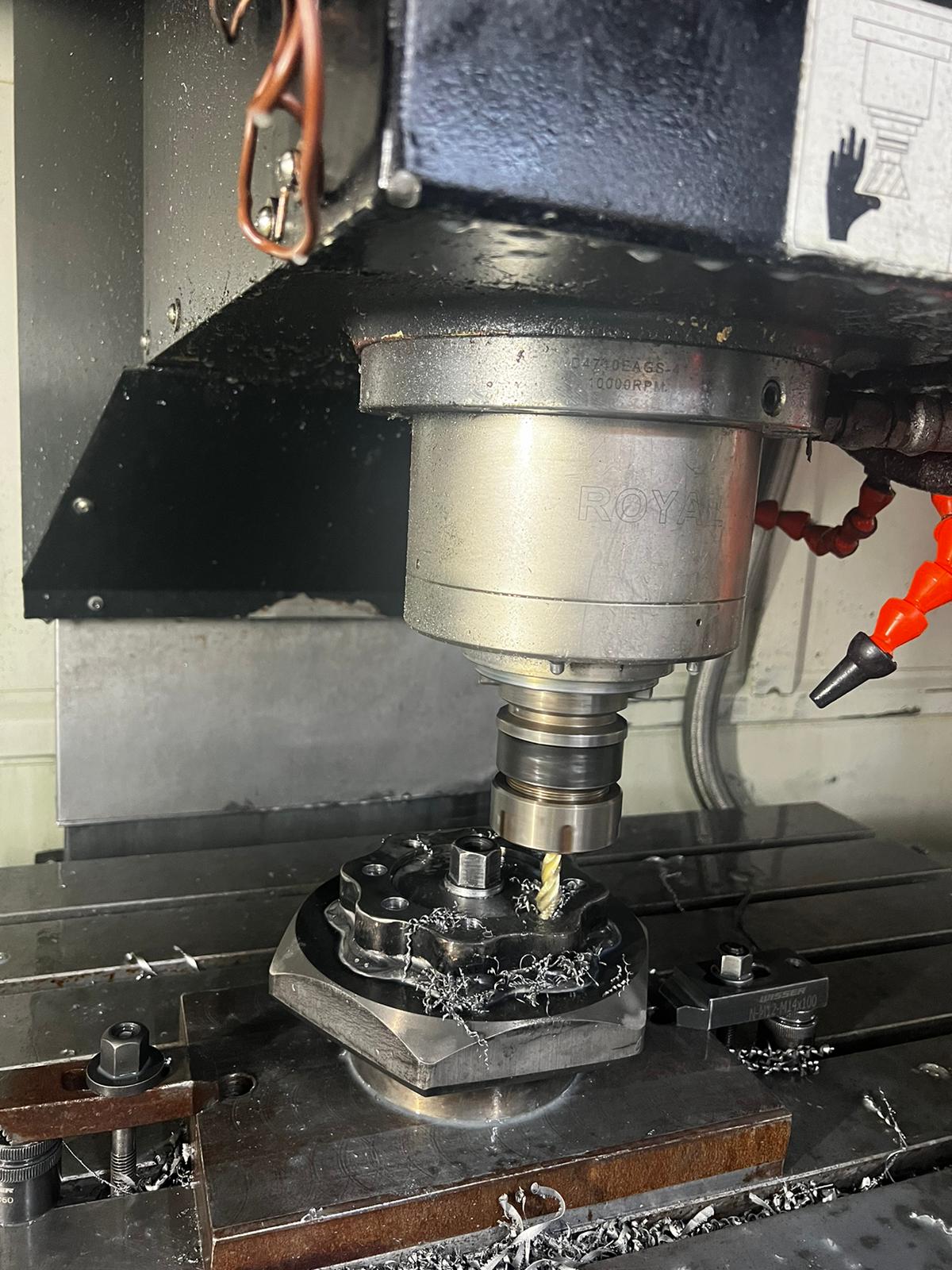

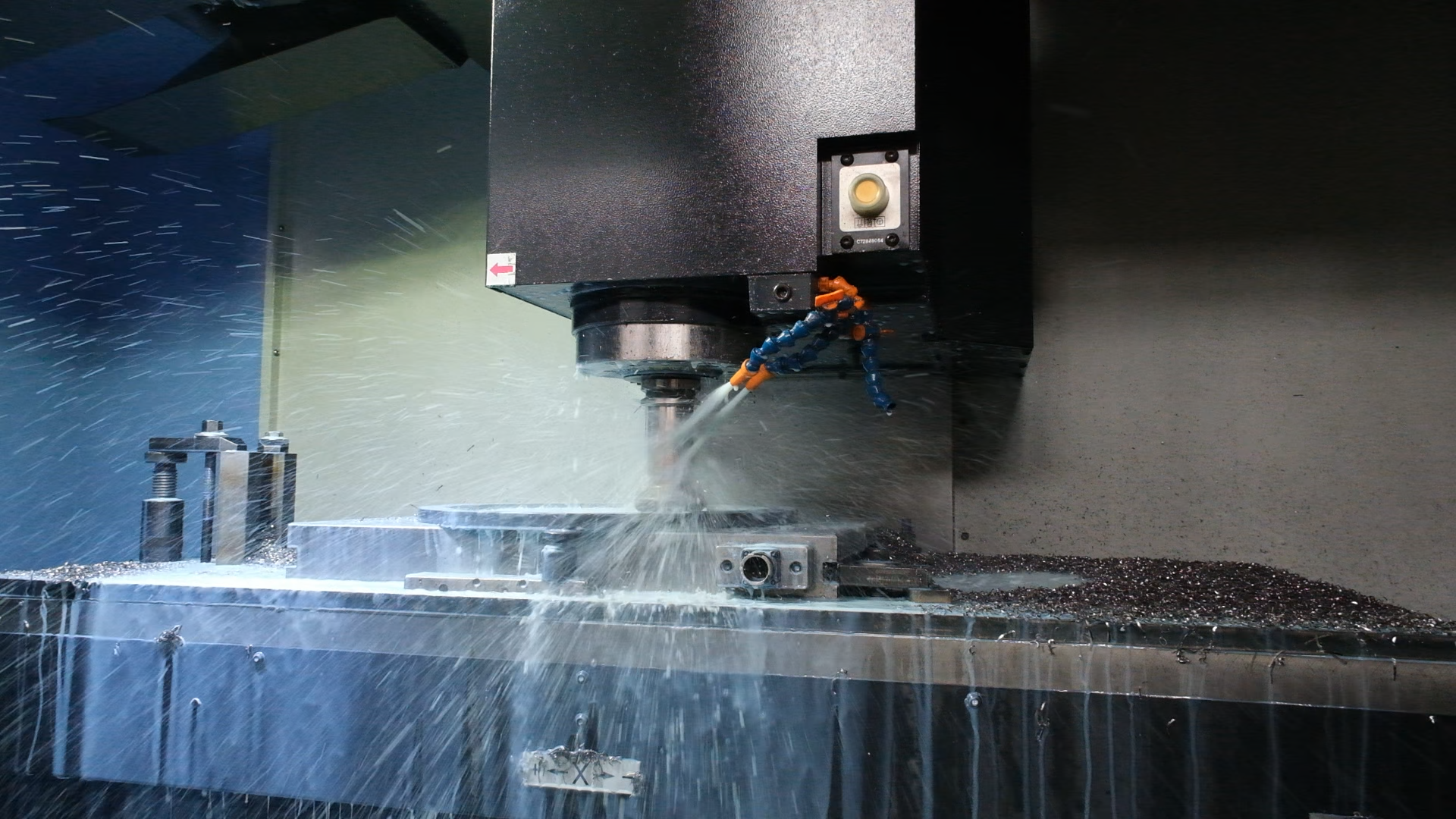

CNC vertical machining technologies enable high-precision machining of complex metal parts. We perform operations such as drilling, milling, and surface machining with millimeter tolerances and in accordance with different material types. Our experienced technical staff offers flexible and high-quality solutions for the production of customer-specific parts.

We carry out high-precision production using lathes and milling machines in metalworking processes. These machines, which are used to shape rotating workpieces, are successfully applied in many processes such as turning, threading, drilling, surface finishing, and conical machining. With our flexible production capacity tailored to different part dimensions and tolerances, we offer reliable solutions for the manufacturing of complex and critical parts.

We are here to help you reduce your workload with our assembly services. All materials with multiple components in press printing or post-painting applications are carefully assembled by our technical and expert team.

We offer high-precision grinding processes for parts that require surface quality and dimensional accuracy. We process hard metals and alloyed materials in accordance with tolerances using modern grinding machines and strict quality control processes.

Industries we serve.

We take pride in providing services for mold and sheet metal materials required in their respective industries, including assembly processes.

- Automotive

- Electrical and Electronics

- Arms Industry

- Hospital Equipment

- Aquatic Products

- Ship Equipment

- Farming Machinery

- Rubber and Packaging Industry

- Decoration Equipment

- Towel rail

- Cage Industry

RESEARCH, DEVELOPMENT, AND INNOVATION

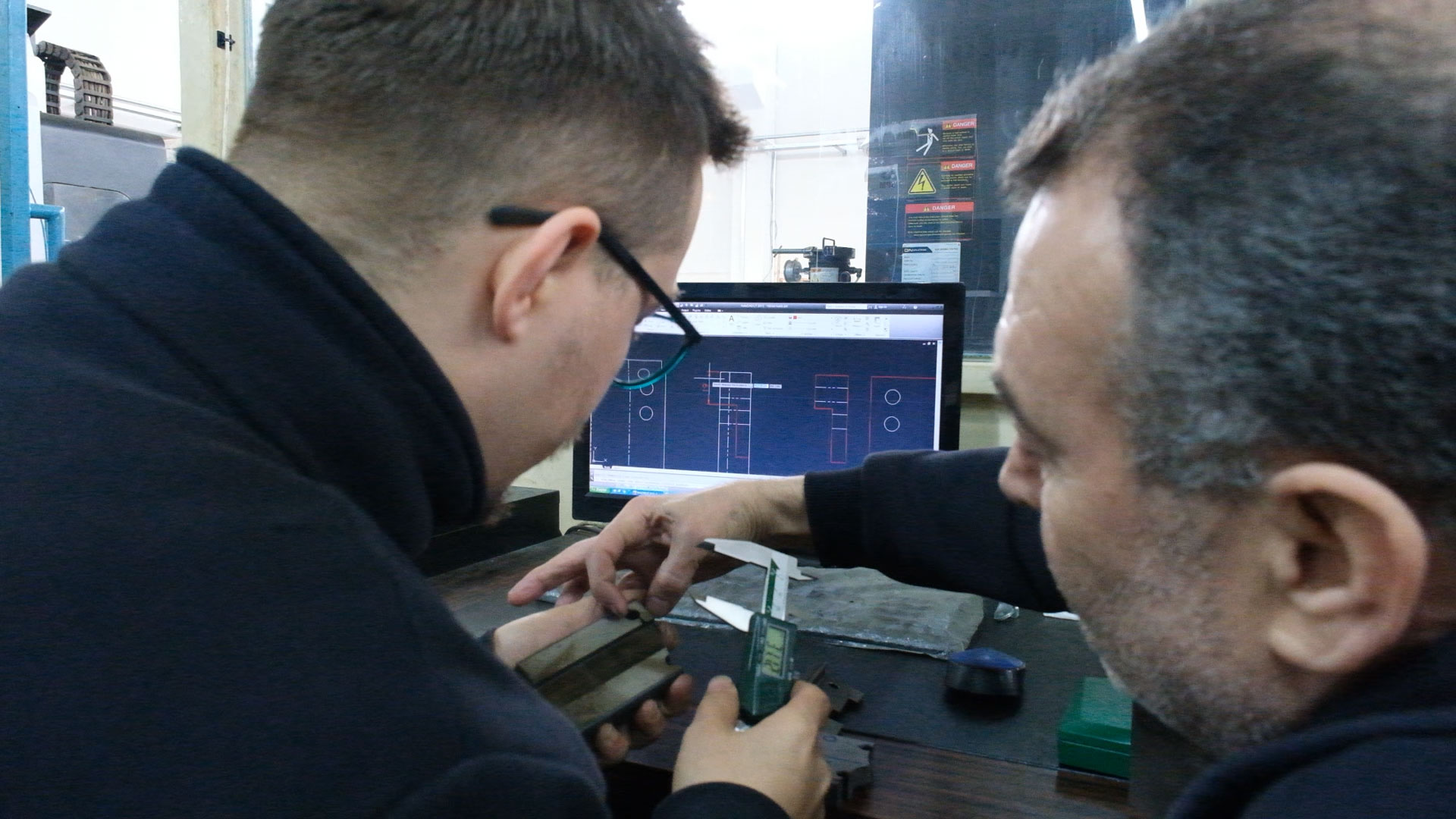

We place great importance on R&D and innovation in line with our goals of creating a livable environment, achieving sustainable economic development, and increasing our competitive strength. We strive to embrace innovation in all areas of life and to produce and acquire knowledge. Joint brainstorming sessions, interviews, brainstorming meetings, workshops, technology panels, and comprehensive analyses form the core processes of our R&D and design work. International standards, as well as the future visions, strategies, and action plans of developed and developing countries, also guide our work. R&D and innovation are also the most fundamental components of competitiveness. Based on this, the opinions and research presented in the joint brainstorming meetings we hold with you are guiding principles for us. At this point, R&D and innovation and their transformation into technological products become essential. In such a challenging struggle, we need to develop high value-added products and increase our revenues by prioritizing technology under the light of R&D and innovation.

As Tunçer Machine Mold Company, we will either do what everyone else does but with much higher quality, efficiency, and at more competitive prices, or we will create awareness by doing what no one else does.

Our Products

What we make

We take pride in providing services for mold and sheet metal materials required in their respective industries, including assembly processes.

Coating Molds

Electricity

Progressive Molds

Cage Equipment

Rubber Support Plates

Ceramic Molds

Automotive

Natural Gas Equipment

Agriculture

PVC Connection Equipment

Decoration

Towel Rail

Tunçer Machıne

Certificates

OUR QUALITY POLICY

As Tunçer Makine Kalıp, our management and employees aim to ensure customer satisfaction and satisfy our stakeholders and society by

- We commit to implementing our quality management system without compromising on product and service quality across all departments

- We commit to collaborating with our customers and business partners through timely and complete deliveries and appropriate pricing policies

- We commit to ensuring the conscious participation of our employees in our operations, as well as providing innovative and appropriate technology and infrastructure